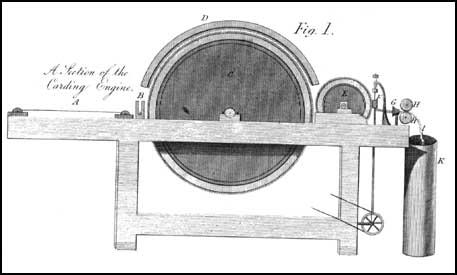

Carding Machine

The invention of the Spinning Jenny and the Spinning Frame caused an increase in demand for cardings. In 1748 Lewis Paul invented a hand driven carding machine. The device involved a card covered with slips of wire placed round a cylinder. Richard Arkwright made improvements in this machine and in 1775 took out a patent for a new Carding Engine. Arkwright's machine included a cylinder carding engine, incorporating a crank and comb mechanism. The comb moved up and down, removing the carded fibres from the doffing cylinder in a "continuous filmy fleece".

Primary Sources

(1) Edward Baines, The History of the Cotton Manufacture (1835)

Lewis Paul's carding patent is dated 30th August, 1748. A copy of which, with the drawings, I have obtained from the Patent Office. The machine had a horizontal cylinder, covered in its whole circumference with parallel rows of cards, with intervening spaces, and turned by a handle.

One of the first improvements made in the carding machine was the fixing of a perpetual revolting cloth, called a feeder, on which a given weight of cotton wool was spread, and, by which it was conveyed to the cylinder. This was invented in 1772, by John Lees, a Quaker, of Manchester.

When Arkwright took out his patent for the carding machine, he also included in it machines for drawing and roving. It consists in drawing out the carding by rollers, and then doubling and redoubling the slivers, which are called ends, so as to restore them to nearly the same substance as at first.

(2) Richard Guest, History of Cotton Manufacture (1823)

The Carding Engine was not invented at once, nor by any particular individual, but was the result of a succession of improvements, made at various times, and by different persons. In this machine a wooden cylinder, covered with cards, turning on an horizontal axis, revolves immediately under a concave cover; the cover is also lined with cards, and the teeth of the cards on the cylinder and of those on the cover, are nearly in contact.

Originally, the cotton was spread upon the cylinder, and the cylinder by its revolutions carded the cotton against the teeth on the cover: the cotton was then taken off the cylinder by hand cards held against it. A great improvement was afterwards made by adding a second cylinder, which took the cotton off the first as fast as it was carded, and a roller, fluted longitudinally, and turning on an horizontal axis, pressed against this second cylinder and rubbed off the carded cotton in stripes.